Schumacher Battery Charger Manual PDF Download: A Comprehensive Guide

Navigating the world of battery maintenance requires accessible resources, and this guide focuses on obtaining Schumacher charger manuals in PDF format, ensuring your device operates optimally.

Specifically, we’ll explore locating documentation for models like SE-2001, SE-3000, SE-4020, SE-4022, SE-6030, and SE-8050, streamlining the process for all users.

Understanding Schumacher Battery Chargers

Schumacher Electric Corporation has a long-standing reputation for producing reliable and innovative battery chargers, maintainers, and jump starters. These devices cater to a broad spectrum of users, from automotive enthusiasts and professional mechanics to everyday individuals needing a dependable power solution. Understanding the core functionalities of a Schumacher charger is crucial for safe and effective operation.

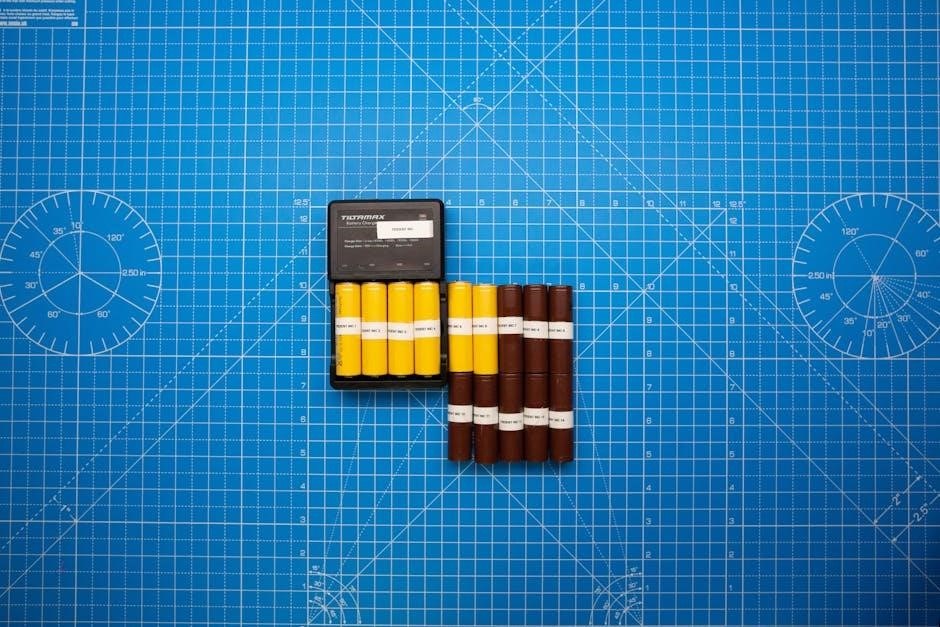

Generally, Schumacher chargers utilize various charging technologies, including trickle charging, fast charging, and maintenance modes, each designed for specific battery types and conditions. The SE-2001, SE-3000, SE-4020, SE-4022, SE-6030, and SE-8050 models, for instance, offer diverse features to accommodate lead-acid, AGM, and gel batteries. Proper usage involves selecting the appropriate charging mode, connecting the clamps with correct polarity, and monitoring the charging process.

Furthermore, familiarizing yourself with the charger’s safety features, such as overcharge protection and reverse polarity protection, is paramount. Consulting the specific manual for your model – available in PDF format – provides detailed instructions and safety guidelines, ensuring optimal performance and longevity of both the charger and the battery.

Popular Schumacher Models Covered

This guide specifically addresses the most frequently sought-after Schumacher battery charger models, ensuring users can readily locate their corresponding manuals. We focus on the SE-2001, a compact and versatile charger ideal for automotive and marine batteries; the SE-3000, known for its robust charging capabilities; and the SE-4020 and SE-4022, offering advanced features like microprocessor control.

Additionally, we cover the SE-6030, a popular choice for heavy-duty applications, and the SE-8050, a sophisticated charger with multiple charging modes and diagnostic functions. These models, often found in both 12V and 24V configurations, represent a significant portion of Schumacher’s product line;

Each model, documented in tri-fold leaflets (English and Spanish, 5-1/2 X 8-1/2 in), typically contains around 49 pages of detailed information, dating back to at least 1990 (9-5-90). Finding the correct PDF manual is essential for maximizing the charger’s performance and ensuring safe operation.

SE-2001 Manual Availability

The Schumacher SE-2001 battery charger manual, a tri-fold leaflet published by Schumacher Electric Corp, is a frequently requested document. While original printed versions date back to at least September 5, 1990, digital PDF copies are readily available through various online resources. Users seeking the SE-2001 manual will find it accessible on third-party manual databases like ManualsLib and ManualsOnline, offering convenient download options.

These online repositories often host scanned copies of the original documentation, providing detailed instructions on operation, safety precautions, and troubleshooting. The manual covers essential aspects of the SE-2001, including charging procedures for different battery types and understanding indicator lights.

Accessing the PDF requires a compatible PDF reader, such as Adobe Acrobat Reader, ensuring clear viewing and printing of the 49-page document.

SE-3000 Manual Availability

Similar to the SE-2001, the Schumacher SE-3000 battery charger manual is available in PDF format through online databases. This model, also documented in a tri-fold leaflet by Schumacher Electric Corp dating back to 1990, benefits from digitized versions readily accessible to users. Platforms like ManualsLib and ManualsOnline serve as key resources for locating and downloading the SE-3000 manual.

The documentation, encompassing 49 pages, provides comprehensive guidance on safe and effective battery charging practices. It details procedures for various battery types, explains the function of controls, and offers troubleshooting tips. Users can expect to find information regarding polarity connection and proper ventilation requirements.

A functional PDF reader, like Adobe Acrobat Reader, is necessary to view and print the manual effectively, ensuring optimal usability.

SE-4020 & 4022 Manual Availability

Finding the manuals for the Schumacher SE-4020 and SE-4022 battery chargers follows a similar pattern to the previously mentioned models. These chargers, also part of the Schumacher Electric Corp’s lineup documented in the 1990 leaflets, have their manuals digitized and available online. Both models share similar functionalities, often resulting in combined or closely related documentation.

Users can locate PDF versions of these manuals on third-party databases such as ManualsLib and ManualsOnline. These resources offer convenient access to the 49-page documentation, covering essential aspects like charging procedures, safety precautions, and troubleshooting steps.

The manuals detail proper battery acid handling, correct polarity connections, and the importance of adequate ventilation during charging. A compatible PDF reader, such as Adobe Acrobat Reader, is crucial for viewing and utilizing these resources effectively.

SE-6030 Manual Availability

Securing the manual for the Schumacher SE-6030 battery charger is readily achievable through online resources. Like the SE-2001, SE-3000, SE-4020, and SE-4022, documentation for this model was included in the 1990 Schumacher Electric Corp leaflets – a tri-fold, 5-1/2 x 8-1/2 inch paperback containing 49 pages of information.

Digital copies of the SE-6030 manual are commonly found on platforms like ManualsLib and ManualsOnline. These databases provide free access to the PDF format, allowing users to download and view the charger’s operational guidelines, safety instructions, and troubleshooting advice.

The manual comprehensively covers essential aspects, including proper ventilation requirements, safe battery acid handling procedures, and the critical importance of maintaining correct polarity during connections. Utilizing Adobe Acrobat Reader ensures optimal viewing and functionality of the PDF document.

SE-8050 Manual Availability

Finding the user manual for the Schumacher SE-8050 battery charger follows a similar pattern to other models in the series – SE-2001, SE-3000, SE-4020, and SE-4022. These chargers were documented in a 1990 publication by Schumacher Electric Corp, a tri-fold leaflet (5-1/2 x 8-1/2 inches) expanding to 16-1/2 inches, comprising 49 pages of detailed instructions.

Fortunately, digital versions of the SE-8050 manual are widely available online. Websites such as ManualsLib and ManualsOnline host PDF copies, offering free downloads for convenient access. These manuals detail crucial information regarding charger operation, safety protocols, and troubleshooting steps.

Users can readily view these PDFs using Adobe Acrobat Reader, the industry standard for PDF viewing and annotation. The manual emphasizes safety precautions, including proper ventilation, battery acid handling, and correct polarity connection, ensuring safe and effective charger use.

Where to Download Schumacher Charger Manuals

Locating Schumacher battery charger manuals, particularly for models like the SE-2001, SE-3000, SE-4020, SE-4022, SE-6030, and SE-8050, is readily achievable through several online avenues. The primary source is the official Schumacher Electric website, which often hosts downloadable PDFs for current and older models. However, for legacy models, alternative resources become invaluable.

Several third-party manual databases offer extensive collections. ManualsLib and ManualsOnline are prominent examples, providing searchable archives of user manuals, including those from Schumacher Electric Corp. These platforms allow users to quickly find and download the specific manual needed, often in PDF format.

Remember to verify the manual’s relevance to your specific charger model and revision date. Utilizing these resources ensures you have access to the correct documentation for safe and effective operation.

Official Schumacher Electric Website

The official Schumacher Electric website serves as the primary and most reliable source for downloading battery charger manuals. Directly accessing the manufacturer’s site ensures you obtain the most accurate and up-to-date documentation for your specific model, including the SE-2001, SE-3000, SE-4020, SE-4022, SE-6030, and SE-8050.

Typically, the website features a dedicated “Support” or “Resources” section where users can search for manuals by model number. The downloadable files are generally in PDF format, compatible with standard PDF readers. This method guarantees compatibility and avoids potential issues with outdated or incorrect information found on third-party sites.

Regularly checking the official website is recommended, as Schumacher Electric may update manuals with revisions or new information. This proactive approach ensures you always have access to the latest guidance for your charger.

Third-Party Manual Databases

When the official Schumacher Electric website doesn’t immediately yield the desired manual – perhaps for older models like the SE-2001, SE-3000, or even the SE-8050 – several third-party manual databases can prove invaluable. These platforms aggregate manuals from various manufacturers, offering a broader search scope.

Two prominent options include ManualsLib and ManualsOnline. These sites allow users to search specifically for “Schumacher battery charger manual” or input the model number directly. While convenient, it’s crucial to verify the manual’s authenticity and revision date, as information may not always be the latest version.

Always exercise caution when downloading from these sources and scan files for potential malware. These databases can be helpful supplements, but the official Schumacher website remains the preferred source for accuracy.

ManualsLib

ManualsLib stands as a widely-used online repository for user manuals, offering a substantial collection including documentation for Schumacher battery chargers. Searching for models such as the SE-2001, SE-3000, SE-4020, or SE-6030 often yields results, potentially providing access to the tri-fold, 49-page leaflets from 1990, covering both English and Spanish versions.

The platform’s interface allows for keyword searches and filtering by brand and model, simplifying the process of locating the correct manual. However, users should carefully review the document’s details – including the publication date (like 9-5-90) – to ensure it corresponds to their specific charger version.

While ManualsLib is a valuable resource, remember to exercise caution and verify the manual’s accuracy before relying on its instructions. Always prioritize safety and consult official sources when possible.

ManualsOnline

ManualsOnline presents another accessible avenue for sourcing Schumacher battery charger manuals in PDF format. Similar to ManualsLib, this platform hosts a diverse range of user guides, potentially including documentation for models like the SE-2001, SE-3000, SE-4020, SE-4022, SE-6030, and SE-8050. Users can navigate the site using keywords or brand-specific searches to pinpoint relevant manuals.

The website often provides previews of the documents, allowing you to confirm the manual’s content before downloading. As with any third-party source, verifying the manual’s date – referencing the 1990 publication date for older models – is crucial to ensure compatibility with your charger.

It’s important to remember that while ManualsOnline offers convenience, always prioritize official documentation when available and exercise caution when interpreting instructions.

PDF Reader Requirements

To effectively access and utilize downloaded Schumacher battery charger manuals, a compatible PDF reader is essential. The universally recognized standard is Adobe Acrobat Reader, available as a free download for Windows, macOS, and Android devices. This software ensures accurate rendering of the manual’s formatting, including diagrams and troubleshooting steps for models like the SE-2001, SE-3000, and beyond.

However, Adobe Acrobat Reader isn’t the sole option. Numerous alternative PDF viewers, such as Foxit Reader or SumatraPDF, offer similar functionality. These alternatives can be beneficial if you prefer a lighter-weight application or have specific system requirements.

Regardless of your chosen reader, ensure it’s updated to the latest version for optimal performance and security. This guarantees compatibility with newer PDF features and protects against potential vulnerabilities.

Adobe Acrobat Reader – Free Download

Adobe Acrobat Reader stands as the gold standard for viewing, printing, signing, and annotating PDF documents, including Schumacher battery charger manuals for models such as the SE-4020, SE-4022, and SE-6030. Downloading this software is straightforward and completely free.

To obtain it, simply visit the official Adobe website and navigate to the Acrobat Reader download section. The installation process is user-friendly and typically completes within minutes. Once installed, you can seamlessly open and interact with all types of PDF content, including forms and manuals.

This software is crucial for correctly displaying the detailed diagrams and troubleshooting guides found within the Schumacher manuals, ensuring you can effectively maintain your charger, even the SE-8050 model.

Alternative PDF Viewers

While Adobe Acrobat Reader is the industry leader, several excellent alternative PDF viewers can access your Schumacher battery charger manuals, including those for the SE-2001 and SE-3000 models. These options provide similar functionality without the need for a full Adobe software suite.

Foxit Reader is a popular choice, known for its speed and lightweight design. SumatraPDF is another excellent, free option, particularly favored for its simplicity and minimal resource usage. Both viewers allow you to open, read, and print PDF files with ease.

These alternatives are beneficial if you encounter compatibility issues or prefer a different user interface. Regardless of your chosen viewer, ensuring you can properly display the manual’s information is vital for safe and effective charger operation, even for the SE-4020.

Troubleshooting Common Issues (Refer to Manual)

Encountering problems with your Schumacher battery charger, be it a SE-2001, SE-3000, or any other model, can be frustrating. However, many issues have straightforward solutions detailed within your charger’s manual. Always consult the manual first before attempting repairs.

Common problems include the charger failing to power on, a battery not receiving a charge, or the appearance of error codes. The manual provides specific troubleshooting steps for each scenario, often relating to connection polarity or voltage settings.

Understanding these error codes, specific to models like the SE-4020 and SE-6030, is crucial for diagnosing the root cause. Remember, attempting to fix issues without proper guidance can be dangerous; the manual is your primary resource for safe and effective troubleshooting;

Charger Not Turning On

If your Schumacher battery charger, whether it’s a SE-2001, SE-3000, or a more recent model like the SE-8050, fails to power on, several factors could be at play. First, verify the power cord is securely connected to both the charger and a functioning electrical outlet. Test the outlet with another device to confirm it’s providing power.

Next, check the charger’s internal fuse – the manual will detail its location and proper replacement procedure. Inspect the power switch itself for any damage or malfunction. A faulty switch may prevent the unit from receiving power.

Consult your charger’s PDF manual for model-specific troubleshooting steps. Ignoring these steps could lead to further damage or safety hazards. Remember, always disconnect the charger from the power source before inspecting internal components.

Battery Not Charging

Encountering a situation where your Schumacher charger isn’t charging the battery, regardless of the model (SE-2001, SE-4020, SE-6030, etc.), requires systematic troubleshooting. Initially, ensure the charger clamps are making a firm, clean connection to the battery terminals. Corrosion or loose connections are common culprits.

Verify correct polarity – red clamp to positive (+), black clamp to negative (-). Reversing polarity can damage both the charger and the battery. Confirm the battery isn’t already fully charged, as some chargers may not indicate a full charge.

Refer to your specific charger’s manual (available as a PDF download) for recommended charging times and voltage settings based on the battery type and capacity. A damaged battery may also prevent charging; testing the battery’s voltage is recommended.

Error Codes & Their Meanings

Schumacher battery chargers, including models SE-2001, SE-3000, SE-4020, and SE-8050, often utilize error codes to signal specific issues. These codes, detailed within your charger’s PDF manual, are crucial for accurate diagnosis. Ignoring these signals can lead to further damage or incorrect repairs.

Common error codes might indicate reversed polarity, a faulty battery, overvoltage, or internal charger malfunctions. The manual provides a comprehensive list, explaining each code’s meaning and suggested corrective actions. For example, a flashing light sequence could denote a battery sulfation issue.

Always consult the manual specific to your charger model, as error code definitions can vary. Downloading the PDF version ensures you have the most up-to-date information for effective troubleshooting and maintenance.

Safety Precautions (Important – See Manual)

Working with battery chargers and batteries presents inherent risks, making adherence to safety precautions paramount. The Schumacher charger manual, available as a PDF download, details critical safety guidelines for models SE-2001 through SE-8050. Ignoring these instructions could result in serious injury or property damage.

Key precautions include ensuring adequate ventilation during charging to prevent hydrogen gas buildup, which is explosive. Always wear appropriate eye protection and gloves when handling batteries, as battery acid is corrosive. Correct polarity connection – red to positive, black to negative – is vital to avoid sparking and potential explosions.

Never charge damaged batteries, and always disconnect the charger before removing the battery. Refer to the manual for specific warnings related to your charger model and battery type. Prioritize safety; the manual is your guide.

Proper Ventilation

Battery charging generates hydrogen gas, a highly flammable and potentially explosive byproduct. Therefore, adequate ventilation is absolutely crucial when using a Schumacher battery charger, regardless of the model – SE-2001, SE-3000, SE-4020, SE-4022, SE-6030, or SE-8050. Charging in a confined space significantly increases the risk of ignition.

Always charge batteries in a well-ventilated area, preferably outdoors or in a garage with open windows and doors. Avoid charging near sparks, flames, or other ignition sources. Ensure there is sufficient airflow to dissipate the hydrogen gas as it’s produced. The Schumacher manual PDF download provides detailed guidance on ventilation requirements for safe operation.

Failure to provide proper ventilation could lead to a dangerous accumulation of hydrogen gas, posing a severe safety hazard. Prioritize a well-ventilated charging environment.

Battery Acid Handling

Battery acid is a corrosive substance, capable of causing severe burns to skin and eyes. When working with batteries – whether charging with a Schumacher SE-2001, SE-3000, SE-4020, SE-4022, SE-6030, or SE-8050 – extreme caution is essential. Always wear appropriate personal protective equipment (PPE), including safety glasses and acid-resistant gloves.

If battery acid comes into contact with skin or eyes, immediately flush the affected area with copious amounts of water for at least 15 minutes and seek medical attention. Neutralize acid spills with baking soda and water. The Schumacher charger manual PDF download will detail specific safety procedures regarding battery acid.

Avoid contact with clothing, as acid can cause damage. Proper handling and disposal of battery acid are crucial for both personal safety and environmental responsibility.

Correct Polarity Connection

Establishing the correct polarity – positive (+) to positive and negative (-) to negative – is paramount when using a Schumacher battery charger, be it a SE-2001, SE-3000, SE-4020, SE-4022, SE-6030, or SE-8050 model. Reversing the polarity can cause significant damage to the battery, the charger, and potentially surrounding electrical systems.

Always double-check the markings on the battery and the charger leads before making any connections. Most batteries clearly indicate the positive and negative terminals. The Schumacher charger manual PDF download will visually demonstrate the correct connection procedure. Incorrect connections can lead to overheating, sparking, and even explosion.

Ensure a secure connection to prevent arcing. Prioritize safety and consult the manual if unsure about the polarity of your battery or charger setup.

Manual Revision Dates & Updates

Schumacher Electric Corp. periodically updates its battery charger manuals, including those for models SE-2001, SE-3000, SE-4020, SE-4022, SE-6030, and SE-8050, to reflect design changes, safety improvements, and new features. Identifying the manual version is crucial to ensure you’re referencing the most accurate information.

Typically, the revision date is located on the cover page or within the introductory section of the PDF manual. Checking for updated manuals is essential, especially if your charger is several years old. Outdated manuals may contain inaccurate instructions or fail to address specific issues with your model.

Regularly visit the official Schumacher Electric website or trusted manual databases like ManualsLib and ManualsOnline to verify you have the latest version. Staying current with manual updates enhances safety and optimizes charger performance.

Identifying Manual Version

Determining the version of your Schumacher battery charger manual – for models like SE-2001, SE-3000, SE-4020, SE-4022, SE-6030, or SE-8050 – is vital for accurate troubleshooting and safe operation. Look for a “Revision Date” or “Version Number” typically found on the manual’s cover page, in the footer, or within the introductory sections of the PDF document.

Often, the date is presented as month/day/year (e.g., 09-05-90, as seen in some Schumacher documentation). Pay close attention to this date, as it indicates when the manual was last updated. A more recent date signifies that the manual incorporates the latest changes and corrections.

If no explicit version number is present, compare the manual’s contents with information available on the Schumacher Electric website to confirm its accuracy.

Checking for Updated Manuals

Regularly verifying if an updated manual exists for your Schumacher charger (SE-2001, SE-3000, SE-4020, SE-4022, SE-6030, or SE-8050) is crucial, as manufacturers often release revisions to address errors, add new features, or enhance safety information. The official Schumacher Electric website is the primary source for the latest documentation.

Periodically visit the website’s support or downloads section and search for your specific model number. Compare the revision date of the online manual with the date on your current PDF copy. If the online version is newer, download and replace your existing manual.

Additionally, check third-party manual databases like ManualsLib and ManualsOnline, but always prioritize the official Schumacher source for accuracy and reliability.

Schumacher Electric Corp. Information

Schumacher Electric Corporation has a rich history in designing and manufacturing automotive battery chargers, jump starters, and related accessories. Founded on a commitment to quality and innovation, the company has become a trusted name for both professional mechanics and DIY enthusiasts. Their product line, including models like the SE-2001, SE-3000, SE-4020, SE-4022, SE-6030, and SE-8050, caters to a wide range of battery charging needs.

For direct support, contacting Schumacher Electric Corp. is straightforward. Visit their official website to find contact information, including phone numbers and email addresses. Their customer support team can assist with manual requests, troubleshooting, and product inquiries. Accessing reliable information directly from the source ensures you have the most accurate guidance for your Schumacher charger.

Company History & Background

Schumacher Electric Corporation boasts a long-standing legacy in the automotive tool and equipment industry, originating as Home Comfort Kraft in 1990. Initially focused on battery chargers for various applications, the company quickly gained recognition for its durable and reliable products. Over the decades, Schumacher expanded its offerings to include jump starters, battery maintainers, and other power-related solutions, serving both professional and consumer markets.

The company’s commitment to innovation led to the development of advanced charging technologies, catering to the evolving needs of modern vehicles. Models like the SE-2001, SE-3000, and subsequent series demonstrate this dedication. Schumacher’s consistent focus on quality and customer satisfaction has solidified its position as a leading brand in battery charging solutions, continually adapting to industry advancements.

Contacting Schumacher Support

For direct assistance with your Schumacher battery charger, or to inquire about manual availability – particularly for models SE-2001, SE-3000, SE-4020, SE-4022, SE-6030, and SE-8050 – reaching out to their support team is crucial. While specific contact details aren’t explicitly provided in readily available sources, Schumacher Electric Corporation generally offers customer service through various channels.

Typically, manufacturers provide support via phone, email, or a dedicated contact form on their official website. Exploring the “Contact Us” section of Schumacher’s website is the first step. Alternatively, searching online for “Schumacher Electric support” will yield current contact information. Having your charger’s model number handy will expedite the process, ensuring efficient assistance with any questions or concerns regarding operation or manuals.